A Partial Discharge Monitoring System for transformers is a cutting-edge solution that plays a pivotal role in safeguarding transformer health. This advanced system enables real-time monitoring and early fault detection, allowing asset owners to proactively address potential issues. By continuously assessing the condition of transformers and identifying partial discharges – a leading indicator of problems – this system ensures reliable power distribution and minimizes the risk of costly downtime. It’s a transformative technology that empowers industries to take a proactive stance in maintaining their transformers and extends the operational life of these critical assets.

GE’s Integrated Solution

Intellix BMT 330 with Kelman TRANSFIX DGA

The Intellix BMT 330 can easily be integrated with GE’s Kelman TRANSFIX DGA analyzer, giving the end user a unique all-in-one solution that provides a more comprehensive view of the transformer’s overall condition, from bushing diagnostics and PD, to complete main tank monitoring.The Kelman TRANSFIX is an 9-gas on-line transformer monitoring unit. Using specially developed advanced photo-acoustic detection technology, the TRANSFIX measures all significant fault gases.

Increased Asset Reliability

Having an all-in-one integrated solution from GE will significantly increase the ability to detect potential transformer problems at an early stage. The system will provide status on:

• Deterioration of the bushing insulation

• Partial discharge activity

• Moisture content in oil

• Developing key fault gases H₂, CO, C₂H₂, C₂H₄, C₂H₆, CO₂ and CH₄

This helps to decrease the risk of unplanned downtime and improve network reliability.

Perception Fleet Software

GE’s Perception Fleet software allows an operator to easily download and visualize the data available from a critical transformer and use it to make better, more informed decisions. It offers ease of use, an intuitive interface, and familiar options that are common across all of GE’s Monitoring and Diagnostic products. The software is an upgradeable tool, allowing users to view all relevant transformer data from one centralized point.

With the Intellix BMT 330, Perception often uses a vector sum on a polar plot to easily highlight what is happening and eliminate common changesaffecting all bushings (load, temperature) that are not a source of concern.

One-vendor Solution Provider

Having a one-vendor providing the complete transformer monitoring solution can effectively lower installation costs, as well as reduce the administrative burden of coordinating various maintenance crews. All products work together and communicate seamlessly with no interface or responsibility issues. GE has extensive experience and worldwide resources available to deliver

integrated monitoring solutions and assist customers with transformer challenges, including installations, commissioning, training and on-going technical support.

Application Examples

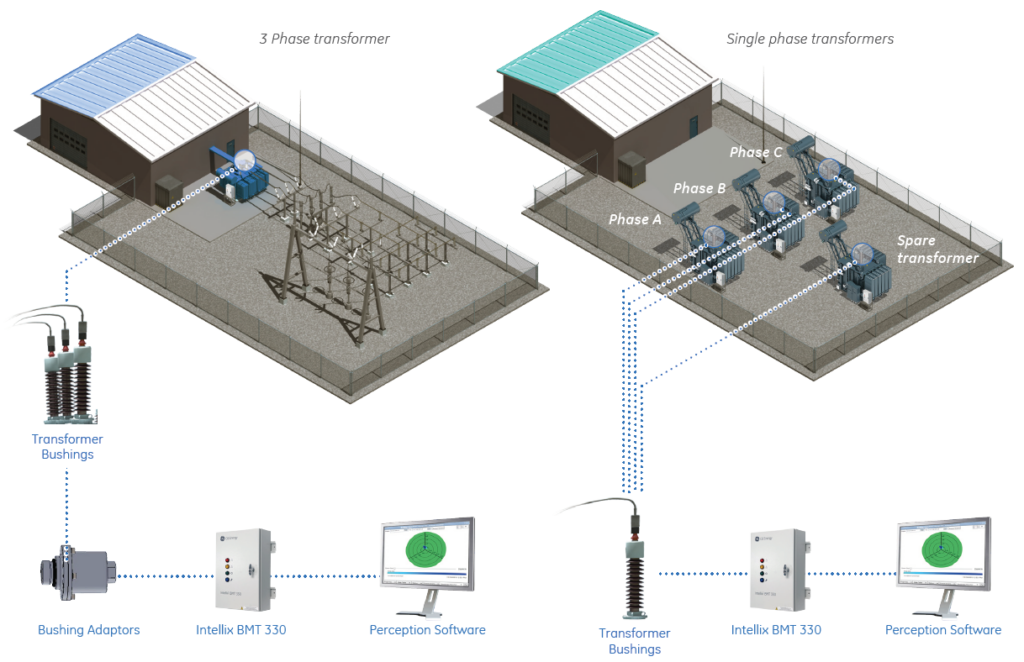

On the left hand side the Intellix BMT 330 is connected to a 3 phase transformer. On the right hand side, the Intellix BMT 330 is being used on a bank of single phase transformers along with a spare transformer. Using external switches a spare transformer can be brought into service replacing one of the bank transformers without interrupting the grid.

In the realm of high-voltage substations, bushings play a pivotal role in ensuring seamless electrical power distribution. However, these components are susceptible to failures, often leading to costly damages and operational disruptions. Historically, asset owners have resorted to preventive maintenance, early replacements, and periodic offline testing to mitigate the risks associated with bushing failures. But the landscape is evolving, and advanced technology now offers a more proactive and cost-effective solution – the Partial Discharge Monitoring System for Transformers. In this comprehensive exploration, we’ll focus on the keyword “Partial Discharge Monitoring System for Transformers” and delve into the intricacies of this cutting-edge solution.

The Significance of Bushing Monitoring and Partial Discharge Detection for Transformers

Bushing Failures: A Pervasive Challenge

Bushing failures are a common cause of high-voltage substation breakdowns, and they can lead to extensive and costly damages. These critical components are constantly under high stress due to line voltage and the heat generated by current flow. Various factors can exacerbate these stresses, including manufacturing imperfections, aging, thermal cycling, pollution, flashovers, sludge accumulation, and moisture in insulating oil. Furthermore, the design limits of new bushings are often pushed to reduce cost, size, and weight. The combination of these factors can lead to the gradual deterioration of bushing insulation. If left undetected, this deterioration can culminate in catastrophic failure, often characterized by violent explosions, extensive oil fires, and shards of porcelain shattering. The consequences extend beyond transformer damage and can include collateral equipment damage, human injuries, environmental liabilities, and contractual penalties.

The Evolution of Bushing Monitoring

Traditionally, bushing testing necessitated taking transformers offline at regular intervals for close inspection, internal oil level monitoring, and capacitance or power factor measurements. This approach, while effective, is impractical due to its disruptive nature and the infrequency of offline testing, which leaves ample room for critical issues to develop between inspections. Modern technology, bolstered by fast electronics, has revolutionized bushing monitoring. Continuous, online monitoring of transformer bushings has become technically feasible, and it is now recognized as a “best practice” for mitigating catastrophic bushing failure.

Introducing the Intellix™ BMT 330: Bushing and Partial Discharge Solution

Real-Time Bushing Condition Assessment

The Intellix™ BMT 330 represents a groundbreaking solution that continuously assesses the condition of bushings in real time, ensuring that asset owners are equipped with the critical information they need. It offers the same data that was previously obtained through offline tests, including changes in capacitance and power factor (tan delta), providing insights into bushing dielectric efficiency and insulation integrity. Utilizing specially designed adaptors connected at the bushing tapping points, the Intellix BMT 330 measures several key parameters:

- Change in Bushing Leakage Current: By comparing the change in leakage current with the original values calculated from the bushing nameplate data and transformer operational voltage, the Intellix BMT 330 can calculate the change in capacitance (C1) compared to the initial installation. This change serves as a gauge for the bushing’s dielectric capability and layer integrity.

- Timing Differences Between Bushing Current Phases: The Intellix BMT 330 also measures the timing differences among the three bushing current phases. These differences translate to phase angle variations relative to each other, indicating changes in power factor. This measurement helps detect even minor deterioration in bushing insulation.

- Environmental Data: The system tracks ambient temperature, humidity, and the temperature of the transformer’s main tank. It correlates changes in capacitance with thermal expansion of the bushing and compensates for differences in measurements made at the actual operating temperature compared to nameplate values obtained offline at 20°C.

Partial Discharge Detection

In addition to bushing monitoring, the Intellix BMT 330 offers the added advantage of measuring high-frequency signals for partial discharge (PD) monitoring. Partial discharge refers to localized breakdown in the electrical insulation system that does not entirely bridge the space between two conductors. This phenomenon occurs under high voltage stress and can lead to gradual erosion of the insulation system, ultimately resulting in critical insulation failure. The Intellix BMT 330 records the amplitude of PD pulses and calculates an overall measure of PD activity. It employs various methods to differentiate between internal PD and external noise (such as corona discharge) and provides Partial Discharge Phase Resolve (PDPR) diagnostics.

How GE’s Intellix BMT 330 Solution Works

Imagine a three-phase transformer with the Intellix BMT 330 solution installed. It constantly monitors the health of bushings, checks for PD activity, and classifies fault types. This detailed monitoring not only guards against catastrophic bushing failure but also calculates transformer aging, helping to avert costly failures. By detecting transformer faults in their early stages, asset owners can respond quickly to remedy the situation. The Intellix BMT 330 offers the following advantages:

- Monitors up to 2 sets of 3 bushings per Intellix BMT 330.

- Provides advanced discrimination using additional sensors.

The Game-Changing Advantages

The Intellix BMT 330 brings an array of advantages that are reshaping transformer health assessment and substation management:

1. Real-Time Analysis: Continuous, real-time monitoring of bushings and PD activity ensures that asset owners are always up to date on their transformer’s condition.

2. Timely Decision-Making: The rapid analysis capabilities empower asset owners to make decisions promptly, whether it’s planning maintenance or addressing emerging issues.

3. Precision and Calibration-Free Operation: Advanced measurement technologies offer unparalleled precision while eliminating the need for frequent calibrations, reducing maintenance demands.

4. Complete Transformer Monitoring: The Intellix BMT 330 can monitor both bushing insulation health and the transformer’s main tank, providing a comprehensive view of the system.

5. Early Warning of Impending Issues: By detecting early warning signs of deterioration and PD activity, the system averts catastrophic failures and ensures the safety of transformers.

6. Robust and User-Friendly: Drawing on over 40 years of experience, GE has designed the Intellix BMT 330 for robust performance, introducing innovative features, an enhanced user experience, and greater system durability.

Who are We?

| Manufacturer |

| supplier |

| trader |

| importer |

| exporter |

| company |

| solution |

Where do we have clients and supply our Partial Discharge Monitoring System For Transformers ?

| India | United Arab Emirates | Uganda |

| Nepal | Israel | Tanzania |

| Vietnam | Egypt | Angola |

| Philippines | Yemen | Kambia |

| Indonesia | Turkey | Malawi |

| Malaysia | Sudan | Botswana |

| South Korea | Algeria | South Africa |

| Oman | Monaco | Zimbabwe |

| Iran | Nigeria | Cambodia |

| Saudi Arabia | Ethiopia | Australia |

| Namibia | Greece | USA |

Advantages of the Partial Discharge Monitoring System for Transformers

The Partial Discharge Monitoring System for Transformers represents a transformative leap in ensuring the reliability and safety of high-voltage substations. By continuously monitoring bushings and detecting partial discharge (PD) activity, this advanced system offers a host of benefits that enhance power distribution system management and safeguard critical assets. Let’s delve into these advantages, emphasizing the keyword “Partial Discharge Monitoring System for Transformers.”

1. Proactive Fault Detection

The system’s real-time monitoring of transformer bushings and PD activity empowers asset owners to proactively detect impending faults. By identifying anomalies and irregularities in a timely manner, it enables operators to take preventive measures and mitigate potential issues before they escalate into costly and catastrophic failures.

2. Improved Decision-Making

Having access to accurate and up-to-the-minute data on transformer health allows for informed and swift decision-making. Operators can promptly initiate maintenance procedures, reducing downtime and minimizing the risk of unplanned outages. The ability to make proactive decisions based on real-time information is invaluable for optimizing operational efficiency.

3. Enhanced Precision

Advanced measurement technologies employed by the Partial Discharge Monitoring System offer exceptional precision in assessing the condition of bushings and monitoring PD activity. This level of accuracy ensures that even minor deteriorations or PD events are not overlooked. The system’s calibration-free operation further contributes to its precision while reducing the need for frequent maintenance.

4. Comprehensive Monitoring

The system provides a holistic view of transformer health by simultaneously monitoring bushing insulation and the transformer’s main tank. This comprehensive approach ensures that no aspect of the transformer’s condition is left unexamined, allowing for a thorough assessment and early warning of any emerging issues.

5. Early Warning System

The system serves as a robust early warning system that signals any deviation from normal transformer operation. It provides alerts at the earliest stages of deterioration or PD activity, allowing operators to intervene promptly and prevent potential catastrophic failures, which can lead to significant damage and costly downtime.

6. Reduced Maintenance Costs

By detecting issues before they escalate, the Partial Discharge Monitoring System helps reduce maintenance costs. Preventive measures can be implemented in a targeted manner, eliminating the need for extensive and costly repairs or replacements. This cost-saving aspect is particularly beneficial for asset owners seeking to optimize their budgets.

7. User-Friendly Operation

Designed with over 40 years of experience, the system is not only precise but also user-friendly. Its intuitive interface and ease of operation contribute to a positive user experience, ensuring that operators can efficiently utilize the technology without the need for extensive training.