- Home

- TOGA / Online DGA

- Online PD

Online PD

Bushing Monitoring and Partial Discharge Detection for Transformers

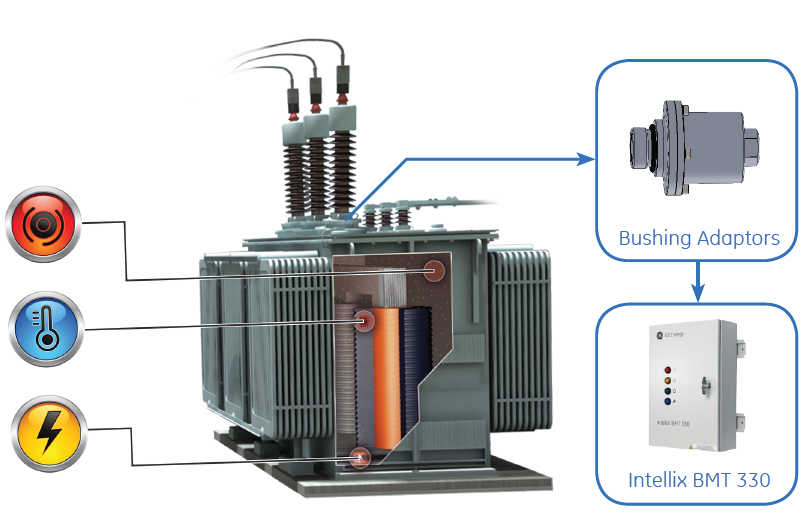

Bushings account for a large proportion of High Voltage (HV) substation failures often causing severe and costly damages. Preventive maintenance, early replacement and regular off-line testing have been employed to address this issue in the past. Now, technology exists that enables asset owners to detect impending failures and reduce their maintenance costs. GE’s IntellixTM BMT 330 is an on-line system that continuously monitors the condition of the bushings and can also detect developing partial discharge (PD) activity in the transformer main tank. It will alert personnel of fault conditions at an early stage and provide vital health information on the bushings and the transformer. The Intellix BMT 330 can be utilized as a standalone system to monitor bushing insulation and partial discharge activity, or as an integrated, one-vendor solution with GE’s KelmanTM TRANSFIX Dissolved Gas Analyzer (DGA) multigas analyzer and PerceptionTM Fleet software providing a more in-depth view of the transformer’s condition and root cause of major transformer failures.

Key Benefits

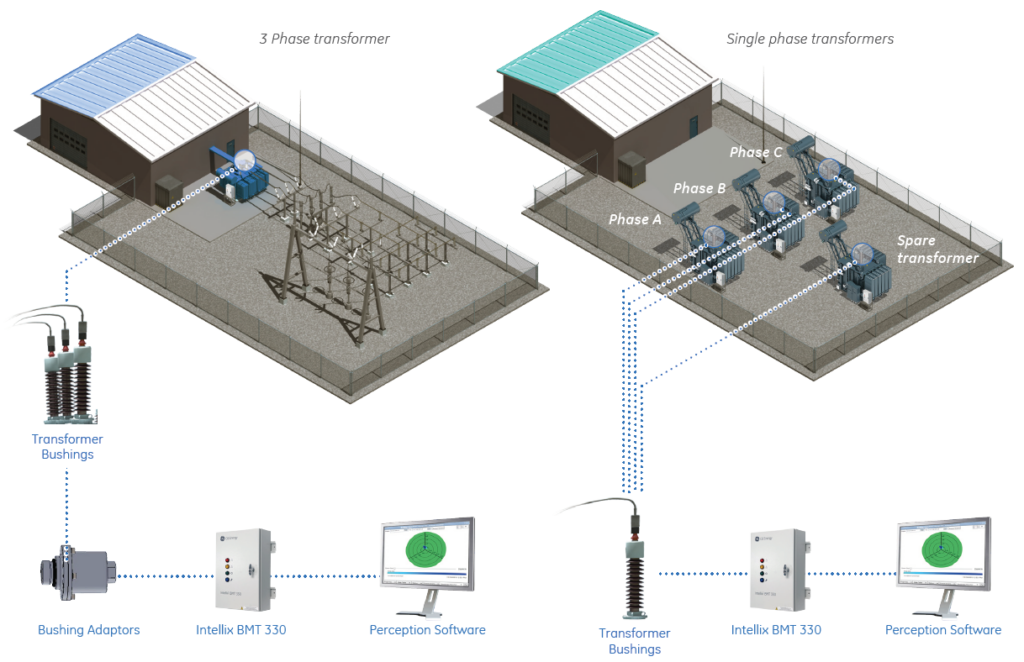

• Comprehensive monitoring of transformer bushings and PD activity on a 3 phase transformer or a bank of 3 single phase transformers.

• One product combining on-line continuous bushing monitoring and partial discharge activity in the transformer main tank using the same bushing adaptor.

• One diagnostic software, GE’s Perception, used for bushing information, PD activity and DGA data analysis, resulting in familiar easy-to-use information.

• One supplier installing, servicing, ensuring proper communication and minimizing administrative burden in order to lower the total cost of ownership of your transformer.

Applications

- Power Utilities

• Enables condition-based maintenance of transformer bushings.

• Designed for various three phase configurations.

- Metals

• Monitors bushing conditions to avoid unplanned production stoppage.

• Monitors PD in over-stressed assets in aluminum or steel mills.

- Petrochemical

• Detects arcing faults with transformers.

• Monitors bushing health to avoid catastrophic failures of transformers.

- Petrochemical

Monitoring Transformer Bushings

Monitoring transformer bushings is critical, because bushings are constantly under high stress due to the line voltage and heat effect of current flow. These stresses can be further aggravated by the presence of micro cracks from manufacturing, loss of mechanical strength due to ageing, repeated thermal cycling (load + sun), pollution and external flash over melting the porcelain, sludge and moisture in the insulating oil, and by the fact that new bushings have been made closer to design limits in order to reduce cost, size and weight. These stresses can cause the insulation of the bushing to deteriorate. If left undetected, this can lead to catastrophic failure in more than half the cases,with violent explosions, large oil fires and broken shards of porcelain flying about. This can result in the total loss of the transformer, collateral damage to nearby equipment, human injuries, environmental claims and fines or contractual penalties. For years, testing bushings meant taking a transformer off-line on a regular basis and closely inspecting the bushings for cracks or imperfections, monitoring the internal oil levels, measuring capacitance within the bushing itself (C1) or measuring the power factor (or tan-delta). Taking a transformer off-line makes this approach impractical, thus minimizing the frequency of testing to once every few years. A critical problem can easily develop in between checks. With modern fast electronics, continuous monitoring of transformer bushings can now be technically achieved. Remote access to the data allows for continuous on-line monitoring of bushings and is now regarded as “best practice” to better guard against catastrophic bushing failure.

The Intellix BMT 330 Bushing Solution

The Intellix BMT 330 continuously monitors the condition of bushings in real time and provides end users with the information they are used to receiving from off-line tests, namely changes in capacitance and power factor (tan delta), to assess the bushing dielectric efficiency and insulation integrity. Using state of the art custom made adaptors connected at the bushing tapping points, the Intellix BMT 330 measures:

• The change in bushing leakage current compared with the original values calculated from the bushing nameplate information and transformer operational voltage. As the change in current is proportional to the change in capacitance, the Intellix BMT 330 calculates the change in capacitance C1 of the bushing compared with when the bushing was installed, to gauge its dielectric capability and layer integrity.

• The timing differences between the 3 bushing current phases, which translate to phase angle differences relative to each other. Since a change of phase delay equates to a change in power factor, we can determine for each bushing the relative (compared to the others) change of power factor as a percentage of the nameplate value. This is used to gauge small deterioration of the bushing insulation.

The Intellix BMT 330 measures ambient temperature, humidity and the temperature of the main tank. It correlates capacitance changes linked to thermal expansion of the bushing and compensates for the measurements being made at actual bushing operating temperature compared with nameplate values obtained off-line at 20°C.

Partial Discharge Detection

PD is a localized breakdown of a small portion of a solid or fluid electrical insulation system that is under high voltage stress, which does not completely bridge the space between two conductors. PD on solid dielectrics

results in localized gradual erosion of the insulation system that eventually leads to failure of critical insulation. Using the same bushing adaptors, the Intellix BMT 330 offers the added advantage of measuring high frequency signals in order to monitor PD activity, giving an added level of protection for the main tank of the

transformer. The amplitude of the PD pulses are recorded and used to calculate an overall measure of PD activity. Several methods are used to discriminate between internal PD and external noise (corona discharge). The BMT 330 also provides Partial Discharge Phase Resolve (PDPR) diagnostics.

Example of GE’s Intellix BMT 330 Solution Installed on a Three-Phase Transformer

Gas analyzer classifies the fault types, providing valuable insights into the transformers condition.

Transformer aging can be calculated so that expensive failures can be avoided.

Transformer faults are detected in their infancy, enabling fast remedial response.

- Through the same bushing tapping points, the Intellix BMT 330 monitors bushing insulation health and checks

for presence of PD activity. - Monitors up to 2 sets of 3 bushings per Intellix BMT 330

- Advanced discrimination using additional sensors

GE’s Integrated Solution

Intellix BMT 330 with Kelman TRANSFIX DGA

The Intellix BMT 330 can easily be integrated with GE’s Kelman TRANSFIX DGA analyzer, giving the end user a unique all-in-one solution that provides a more comprehensive view of the transformer’s overall condition, from bushing diagnostics and PD, to complete main tank monitoring.The Kelman TRANSFIX is an 9-gas on-line transformer monitoring unit. Using specially developed advanced photo-acoustic detection technology, the TRANSFIX measures all significant fault gases.

Increased Asset Reliability

Having an all-in-one integrated solution from GE will significantly increase the ability to detect potential transformer problems at an early stage. The system will provide status on:

• Deterioration of the bushing insulation

• Partial discharge activity

• Moisture content in oil

• Developing key fault gases H₂, CO, C₂H₂, C₂H₄, C₂H₆, CO₂ and CH₄

This helps to decrease the risk of unplanned downtime and improve network reliability.

Perception Fleet Software

GE’s Perception Fleet software allows an operator to easily download and visualize the data available from a critical transformer and use it to make better, more informed decisions. It offers ease of use, an intuitive interface, and familiar options that are common across all of GE’s Monitoring and Diagnostic products. The software is an upgradeable tool, allowing users to view all relevant transformer data from one centralized point.

With the Intellix BMT 330, Perception often uses a vector sum on a polar plot to easily highlight what is happening and eliminate common changesaffecting all bushings (load, temperature) that are not a source of concern.

One-vendor Solution Provider

Having a one-vendor providing the complete transformer monitoring solution can effectively lower installation costs, as well as reduce the administrative burden of coordinating various maintenance crews. All products work together and communicate seamlessly with no interface or responsibility issues. GE has extensive experience and worldwide resources available to deliver

integrated monitoring solutions and assist customers with transformer challenges, including installations, commissioning, training and on-going technical support.

Application Examples

On the left hand side the Intellix BMT 330 is connected to a 3 phase transformer. On the right hand side, the Intellix BMT 330 is being used on a bank of single phase transformers along with a spare transformer. Using external switches a spare transformer can be brought into service replacing one of the bank transformers without interrupting the grid.

Related products

Head Space TOGA Analyzer

The Touch Screen GC System Model Dhruva S2TS.

P–Micro DGA Analyzer

This equipment can be used to detect the incipient fault in the transformer.

Online DGA

Dissolved Gas Analysis (DGA) and moisture measurement of insulating fluids.

Portable DGA

Dissolved Gas Analysis (DGA) and moisture measurement of insulating fluids

Online Transformer Monitoring system

Faced with increasing pressure to continuously improve network availability.